(Note, much of the following relates to the drying of sawn, square-edged timber, but the principles involved are also appropriate to the drying of wood in other forms).

At its simplest air drying wood involves constructing stacks of sawn wood and leaving the stock to dry making use of the wind and the sun.

We have only limited control over the effects of the wind and the sun and this is effected via the correct placement and construction of the stack of wood to be dried.

In Europe (though not in all countries in the world) we generally try to accelerate the process of air drying wood.

At one time it was believed that air drying wood produced wood that was of superior quality to wood which had been dried in a kiln - there is in fact little evidence to support this idea, other than the benefit of the more gradual dissipation of drying stresses which can occur when good quality air dried wood is stored properly and moisture gradients across the wood cross section allowed to even out (such stresses in dried wood can be deleterious and cause a number of defects in the dried wood).

However a serious limitation of air drying wood in the UK (and similar climates) is the minimum moisture content attainable, due to the prevailing climate: in winter only as low as 23% can be attained, whilst even in summer 17% is the lowest moisture content that can be obtained. These values are not low enough for most indoor applications. So in Europe we must, in addition to air drying wood, subsequently kiln dry for indoor applications.

Note: it is well worth considering the The Advantages of Kiln Drying Timber Compared to Air Seasoning of Timber.

In Europe air drying times are long. Approximate drying times are:-

When the air drying of softwood timber is commenced in the spring season (so that drying can occur over the summer season, as softwood species, being more permeable than hardwood species, can tolerate 'rapid' drying), times of drying can be:

Hardwood species are less permeable than softwood species and therfore cannot tolerate 'rapid' drying) so air drying of hardwood timber is best commenced during the cooler seasons, perhaps the autumn season. Times of drying can be:

For an introduction to the permeability of wood see The Structures of Softwoods and Hardwoods and their effect on Wood Drying.

The following are important principles for the design and efficient functioning of an area used to air dry wood.

Where possible:

For valuable stock, stacks might be build inside specially designed “drying sheds” (having e.g. movable louvres to control air flow). Simple “Dutch barns” can also be used – it is important however that such sheds are not overcrowded – this would be a false economy as relatively easy access is necessary to remove individual stacks when required.

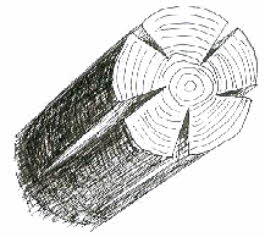

Note that large diameter logs are best sawn ‘green' (i.e. little or no drying has occurred). However if logs are stored for a long time before sawing logs may dry and their ends may suffer from 'end-splitting':-

To avoid end-splitting it might be tempting to nail metal sheets on the ends of the logs: this is in fact bad practice as the restraining metal will cause damage to the wood as it shrinks. It is much more preferable to inhibit drying of the logs by painting their ends with a flexible bituminous or rubber based paint.