Seasoning or drying defects in sawn timber are second only to knots in reducing the quality of processed wood. Once timber has dried below the Fibre Saturation Point (FSP) which is about 28% moisture content, the wood begins to shrink.

Shrinkage of wood is anisoptopic. Shrinkage tangential to the growth rings is greater than in the radial direction, which in turn is much greater than in the longitudinal direction. Furthermore, shrinkage in the outer parts of the wood will occur sooner than in the inner regions. Due to this difference in rates of shrinkage, stresses build up in the wood. Such stresses can lead to distortion, or rupture of the wood, or may remain unnoticed until the wood product is further processed. With high temperature kilning there is potential for these stresses to be relieved as the wood is able to flow to some extent. The amount of shrinkage depends upon the anisotropic nature of the material and upon the way in which the drying was controlled.

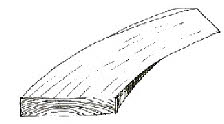

This is caused by anisotropic shrinkage acting on spiral grain or areas where there are density variations in the wood.

Weighting of the stack can help reduce the occurrence of twisting.

This drying defect in sawn timber arises due to the effect of growth ring orientation: - one face of a board is more “tangential” (and therefore shrinks more) than the other face. This is a problem if a log is “flat-sawn”, not if it is “quarter-sawn”. Case hardened boards will also cup if re-sawn.

In the diagram below AD (being more “tangential” than BC) shrinks more than BC (being more “radial”) and therefore the cross-section distorts:-

This is a warping “end to end”. It is caused by stickers being too far apart (too few stickers are used), or if reaction wood is present in the board:-

Here the board remains flat, but bends. It is caused by the release on sawing of growth stresses which occur in large trees. Spring can be reduced by careful stacking.

Knots which are not integral with the surrounding tissue (often surrounded by bark). These knots fall out or protrude during the drying process and may snag in machines on further processing.

In the timber trade ruptures of the dried timber has specific names:-

These are superficial ruptures which do not go right through the board. The incidence of these “checks” can be reduced by end-coating (using flexible, impermeable paint) or shading the end of the board from the sun using a sticker.

These are ruptures that do go right through a board from one face to the other.

These are ruptures in large pieces of timber (e.g. logs). Shakes can also be caused by bad felling techniques, although it is believed that trees grown on certain sites are especially prone to this defect.